For Pre-casters

We extend our consultancy services to precasters to meet the precast PPVC/Modular deliverables for precast PPVC/Modular construction projects. The new technology of modular construction is driving a shift in how production factories are built and operated. We team up with you to tackle all the challenges of this new construction era, ensuring that you can compete in the market successfully in both the short and long term. Our solutions will enhance the competency and capacity of any precaster to align with the world’s current trends in sustainable construction.

We offer various solutions to support you in making your precast deliverables unique and competitive:

1. Advisory on Prefabrication of Precast Elements:

2. Precast Production Factory Setup:

3. Precast Finishing / Assembling Factory:

4. Digitalization of Precast Tracking System:

5. Batching Plant / Concrete Distribution System

6. Automation / Pallet Circulation / Carousel System / Storage Racks:

7. Mould Vendors & Mould Fabrication

- mostbet az

- pinup azerbaycan

- pin up

- mostbet casino

- mostbet kz

- mostbet казино

- pin up

- mosbet casino

- 4rabet pakistan

- pinup uz

- pinko

- mostbet uz

- mosbet

- pin up

- 1 win

- pinup az

- 1 win

- 1 win casino

- 1win

- mosbet

- mosbet kz

- pinco casino

- pin up india

- pinco

- pinco casino

- pinko casino

- lusky jet

- mostbet kz

- pinco slot

- 1 win kz

- pinup uz

1. Advisory on Prefabrication of Precast Elements

We are experts in modular/PPVC precast solutions, offering cost-effective and innovative design and build alternatives for precast concrete products and systems. Our understanding of modular precast and conventional 2D precast components enables us to deliver creative design and detailing. We focus on reducing time, manpower, and costs by providing total precast solutions.

We assist in managing structural design, detailing, shop drawings, technical coordination, production management, and QSHE, ensuring successful precast project delivery.

As a multiservice precast engineering, consulting, and management firm, we provide cost-effective solutions through creative designs, innovative products, and efficient techniques. We promote precast technology, delivering value through our engineering expertise and deep understanding of the construction lifecycle, ensuring reliability and confidence for our clients.

2. Precast Production Factory Setup

We provide expertise in feasibility studies, technology, and implementation for setting up precast modular/PPVC concrete production factories. We offer tailored solutions for factory setup based on client needs, cost, and capacity, including the required machinery and equipment. We also assist in estimating precast concrete projects during both the tender and execution stages.

Our services include:

- Proposing the required production facility plot area based on production capacity, covering areas for production, storage, concrete mixing (if needed), moulds, workshops, stores/offices, and circulation for both short- and long-term projects.

- Designing an efficient production system to meet daily production targets.

- Estimating setup costs, including:

- Capital costs: production and storage areas, common structures, equipment, and workshop tools.

- Direct costs: raw materials, consumables, moulds, insulation, manpower, and grouting.

- Contingencies and wastage.

- Running costs.

- Recommending an efficient combination of equipment to meet production targets and project budget (Optional).

- Proposing alternative precast layout ideas to reduce overall project costs.

- Estimating manpower requirements and providing production training, including QAQC checks (Optional).

- Proposing tentative setup activities and timelines for the factory.

3. Precast Finishing / Assembling Factory

The PPVC fit-up factory is crucial for saving project time and costs, as the methodology relies on pre-finishing and off-site finishing. The setup, machinery, equipment, area allocation, work sequence, methodology, SOPs, logistics, and operations are key to the success of both the concept and the project. With our experience in establishing and operating fit-up factories, we offer guidance on setting up and managing fit-up factory operations in line with site installation.

Optional Services:

- Supervision and training for workers on assembly, work sequence, and logistics (excluding trade skills).

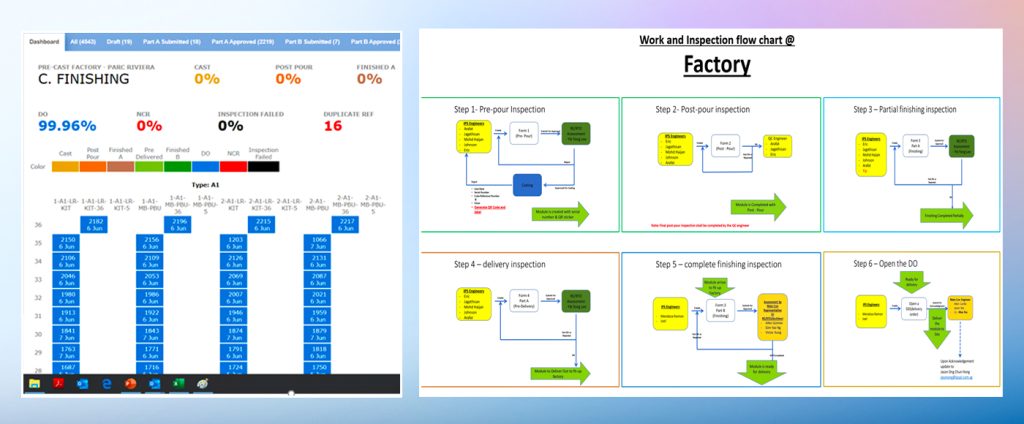

4. Digitalization of Precast Tracking System

For any Construction with PPVC/Precast planning and scheduling is the most importance for the smooth deliverable of the project and the time saving of the project period. Precast production, delivery, and the process of modules are crucial for the smooth construction process. Especially the sequence and status of the components are very essential for the planning and operation of the project. That also will help to streamline the installation of the module, with the proper time management, or with JIT operations. We have a centralized precast tracking system fully digitalized and comes with a sustainable solution to the environment with no papers, which can enhance the entire traceability of the precast production until installation. Such a system also can be collaborated with shop drawings, details, architectural features, all kinds of inspection forms, approval, and relevant photographs and QR codes with QC sticker. The entire documents can be accessible in cloud storage and any modules can be traceable via QR code or mobile applications in real-time monitoring.

5. Batching Plant / Concrete Distribution System

We promote concrete Precast PPVC/Modular construction projects, where concrete is the essential raw material for producing precast products. Owning a concrete batching plant is the most cost-effective solution for long-term concrete supply and distribution, as it is crucial to the production process.

We offer consultancy services by assessing the requirements and addressing the limitations of production factory capacity. With experience working alongside global suppliers, we guide precasters in successfully establishing batching plants and concrete distribution systems. Our services include setting up production facilities, concrete supply and distribution needs, batching requirements, material storage, and raw material supply. We can collaborate with you in liaising with batching plant suppliers and provide technical guidance and support.

6. Automation / Pallet Circulation / Carousel System / Storage Racks

We have experience in establishing Integrated Construction and Precast Hubs (ICPH) in Singapore, where production facilities were combined with concrete supply, precast production, and automated systems. This includes pallet circulation systems, elevated floor shifting, automated storage racks, and coordinating technical design with vendors through to full commissioning.

We’re eager to share our expertise with precasters seeking to enhance their factories for long-term efficiency. Our input, combined with careful planning, can significantly reduce costs in terms of manpower and materials. Our deep understanding of precast concrete equipment and workflows enables us to design and establish economical, high-efficiency plants.

7. Mould Vendors & Mould Fabrication

With our extensive knowledge of modular precast concrete products and conventional 2D precast components, we assist in sourcing and coordinating the procurement of high-quality precast moulds and shuttering systems. While we don’t supply or design moulds, we collaborate with trusted mould vendors globally to help you acquire the right moulds for your project needs. Our goal is to ensure that the moulds are optimized for efficient production and high-quality results.

Our services include:

- Modularization from drawings

- Mould grouping studies to maximize repetition

- Engineering changes and counter proposals

- Coordination with mould vendors on schedules and designs

- Assistance with mould specification detailing and fabrication drawings

- Support in managing mould contracts

- Supervision during fabrication, installation, commissioning, and first casting

- Training on mould operations (optional)

- Advice on mould improvements and alterations

Design Support

- PE design/ Drawings/ Calculation

Drafting support

- BIM modelling, Tekla, Revit, Planbar & Auticad

Project Management

- Technical support during tender, Technical Support during design and conceptualization, Post tender coordination, Project Coordination, Production coordination, QAQC documentation.

QAQC Management

- Standard operating procedurs, Project Quality Plans, Project QAQC documents, Method of Statements

// Check It Out //

Our Services

We have provided our clients with cost effective and innovative alternate design and build solutions in implementing precast concrete products and systems on their precast construction projects. Our involvement in proposing and implementing Total Precast solutions have saved clients time and manpower and ultimately saving the cost. We have assisted our clients in management of structural design, detailing and shop drawings as well as technical coordination for the precast construction projects.

Our services also include,

- Precast concrete concept design proposals

- Alternate design solutions involving use of precast products instead or along with other building materials and implement new precast systems wherever viable.

- Precast elements design detailing and shop drawings

- Precast connection design and detailing

- BIM Modelling and CAD engineering

Our Services

- Precast Engineering

- Precast Project management and consultancy

- Precast production facility setup

- Precast feasibility studies/costing/Estimation

- Precast factory audit and QC services

- Value added support services for precast works

- Precast mould consultancy

- Precast staircase consultancy

- Precast Innovative products and techniques

Precast Guidelines

- History of Precast concrete

- Precast concerte Products

- Engineering of precast panels and structures

- Precast concrete panel moulds

- Production of precast concrete panels

- Storage of precast concrete panels

- Transport of precast concrete panels

- Precast concrete Repairs and finishing

- Installation of precast concrete panels

- Precast concrete structures and systems

- Precast concrete connections

- Precast concrete quality control

- Presterssed Precast concrete

- Architectural/Decorative precast concrete

- Precast concrete Manuals

Who we are

We are a multiservice precast engineering, consulting and management firm. We specialize in precast engineering, construction and plant setup. We provide cost effective solutions to precast buildings and structures through creative and inventive products, designs, processes, and techniques

What we do

We promote precast technology. We commit to making our services benefitting client in every aspect of building and infrastructure construction involving precast components through our precast engineering expertise, value engineering techniques and deep understanding of construction products and project life cycle. We deliver dependability and confidence

Resource

We have assisted our clients in scheduling and planning big precast construction projects along with project supervision and inspection of precast works on site. Our expertise have saved client valuable time due to apt decision making regarding critical site issues pertaining to precast construction. Our involvement in project and technical coordination has given client a comfort level in project execution.

Our services also include,

- Precast factory management and erection management

- Site supervision and inspections of precast works

- Precast works and construction schemes /plans

- QA/QC services of precast works

- Design and Build’ Precast Project Consulting

- Client representative

- Recruitment of specialized manpower for precast factories and sites.

- Review and checking of precast designs and shop drawings

- Sales and Marketing of precast construction projects and products

We have assisted clients in establishing automated, semi-automated, on-site, temporary, mobile and prestressed precast production facilities. So far we have been successful in providing consultancy for 15 such setups in Middle East and India. Our valuable input and meticulous planning have saved clients lot of money for such setups in terms of manpower and materials. Our thorough understanding of precast concrete equipments and work process has given us cutting edge in establishing economical yet efficient plants.

Our services also include,

- Precast Prestressing facility setup including design of beds, sourcing suppliers, and equipment and trial production.

- Precast production management

- Supervision and inspections of works during Factory/Plant setup

- Liaising with precast equipment suppliers

- Technical guidance and support

We have carried out various feasibilities studies pertaining to precast concrete plant setups and assisted our clients in cost and estimation of precast concrete projects during tender stage as well as execution stage.

Our services include,

- Study precast concept drawings received from client and understand project requirements and specifications

- Work out quantities of precast elements in terms of numbers, cubic meter and area

- Propose tentative production facility plot area required as per production capacity which includes areas for production,storage,concrete mixing (if required),moulds,workshops,stores / office and circulation

- Work out and propose efficient product system in terms of production process and equipments to achieve daily production target set by client

- Work out the production facility setup cost in terms of following

- Capital cost which includes cost related to production and storage areas, common structures, miscellaneous structures, production equipments,erection equipments, transport and storage equipments and common workshop equipments

- Direct cost of precast structure (if required) which will include costs of raw materials, consumables, accessories, insulation, moulds, manpower and grouting etc.

- PMC and engineering cost

- Contingencies and wastage

- Running cost

- Work out and propose efficient combination of equipments to achieve proposed production target and project budget and program

- Propose alternate ideas (if any) on the precast layout provided which helps in reducing overall cost of project

- Workout manpower requirement for the setup

- Work out and proposed tentative precast facility setup works activities and program

Our understanding of various precast concrete products and their manufacturing technique helped us in providing out-of-box design and detailing of precast moulds and shuttering systems for the same. Our designs of the moulds and shuttering ensures easier and efficient production.Our goal is to design moulds which can produce high quality precast concrete elements for intended repetitions thus providing value to clients’ money .Our designed precast moulds can be operated and handled with minimum labour and time.

Our services include,

- Precast elements mould scheme and designs

- Precast element mould detailing and fabrication drawings

- Supervision during fabrication and installation

replica uhren schweiz

Swiss best replica watches UK + Top 1:1 Fake rolex replica Watches Hot Sale!